Husqvarna HiPERFLOOR

Concrete has proven to be one of the most durable surfaces known to man. Our civilization has used concrete for over 2000 years, with the Roman Empire utilizing the material widely in Rome. Fast forward a few centuries and little has changed. Concrete is the most widely used construction material in the world by tonnage. Now with the introduction of modern machining techniques, we are now able to grind and polish concrete to unveil its hidden inner beauty and produce a mirror-like finish. Throw in decorative aggregates, such as glass, and concrete can be transformed into a true work of art.

Environmentally friendly

HiPERFLOOR is the smart choice to reduce environmental impact. The process transforms the substrate into a wear-resistant floor. The process incorporates the use of products that cause very little environmental stress or waste.

Hard and resistant

With the HiPERFLOOR method, we take an already hard material and increase the surface density and abrasion resistance to a level where the concrete surface is extremely resistant to wear and marking.

Durable and cost efficient

The HiPERFLOOR concrete polishing system significantly increases durability and reduces life maintenance costs. The absence of a surface coating reduces costs typically related to flooring installations. The result is a smoother surface with reduced cleaning costs.

A HiPERFLOOR can be custom tailored to fit any requirement or taste - flatness, gloss, aggregate exposure, and cost.

And with an available 10 year warranty, a HiPERFLOOR will prove itself to be the best flooring solution for your project.

Welcome to the HiPERFLOOR

The HiPERFLOOR system is different than simple 'Grind and Seals' or a '3 Step System'. A HiPERFLOOR is a complete multi-step process that takes advantage of multiple passes increasing the grit size incrementally for greater control over depth of the grind, flatness, smoothness, shine, and ultimately the longevity of the surface. When creating a polished concrete floor with specialized 'seeded' aggregates it is vital to accurately control the grind depth, otherwise risk grinding through the 'seeds' and losing them forever.

-

Concrete repair and control joint preperation

-

Grinding down to achieve desired aggregate exposure

-

Grouting and filling of all holes/vacancies in the concrete

-

Hardening the concrete with a silicate/lithium based hardener

-

Polishing the concrete until a desired reflectivity is achieved

-

Applying several coats of Guard to enhance color/stain resistance

-

Burnishing the concrete to maximize sheen

The HiPERFLOOR does not warrant a topical sealer usually seen in 'Grind and Seals'. The HiPERFLOOR's shine is mechanically created resulting in a shine and finish that is 'All Natural'. This eliminates the risk of bubbling, peeling and discoloration resulting in a much more permanent and durable shine that will last a lifetime with minimal maintenance costs. In addition to reduced maintenance costs, there is also the added benefit of reduced lighting requirements due to the reflectivity of the surface, sometimes as much as 25%-35%.

Lifetime Maintenance Costs

The HiPERFLOOR consists of several distinct phases:

The HiPERFLOOR Process

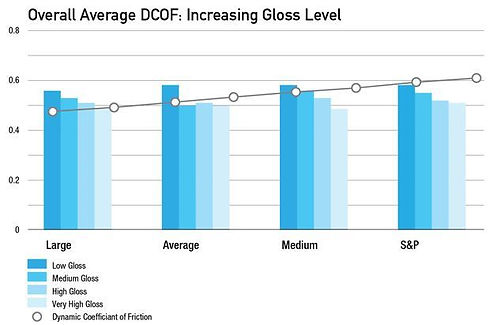

One frequent question we receive when an individual encounters a highly polished HiPERFLOOR is, "Is it slippery?" Although polished concrete's glass like surface and sheen would certainly bring to mind that question, the fact of the matter is quite the opposite. According to a 2014 CPAA Research Study a properly polished concrete floor may be THE most slip resistant floor. "This revelation came out of CPAA-sponsored field workshops where a battery of tests was performed, including measurements of dynamic coefficient of friction (DCOF). It was determined that people walking on polished concrete floors will slip less often than those on almost any other floor."

"Floors with a high traction rating present a low risk of slip and fall, while those with moderate and low traction present elevated risk for slips, trips and falls. The appropriate levels of slip resistance for a particular type of surface depend on the risk assessment of the material manufacturer and owner of the installed walkway. For example, the Tile Council of North America requires a minimum DCOF value of 0.42 for ceramic floors to be walked on wet. Interestingly, the initial results of the CPAA workshops indicate that a wide array of polished concrete finishes provide wet DCOF measurements of 0.50 and higher, well above what is considered to be high traction."

This makes polished concrete one of the safest floors available for schools, libraries, hospitals, churches, high traffic commercial areas, and last but not least, the home.

Polished Concrete Slip Resistance

Only a Husqvarna certified contractor in conjuntion with Husqvarna premium grinding equiptment, diamond tooling, and chemicals can transform a floor into a HiPERFLOOR.

The HiPERFLOOR process will transform the surface of both new and existing concrete into a flooring solution with a whole new level of beauty, functionality, and strength.

Easy Maintenance, extremely long life, and protected with a manufacturer's warranty up to 10 years; makes HiPERFLOOR the perfect choice!